Being built by Ben Trowbridge

Page 1 of 4

Next Page>>

Ben started this 50% cub in December 2009. The wing span will be approx. 18 foot 6 inches

He is considering doing it in US Army colours..

Underside of one wing panel. Ribs are 1/8" light ply (used a whole 8'x4' sheet to cut out enough ribs and sub ribs for both wings!!) Will post more pictures later of how I cut them out.

4 x Main spars, 15mm x 15mm square, light weight hard wood.

Sheet webbing is 3/16 hard balsa apart from the 2 darker areas (half way along wing) which is the same light ply as ribs. These areas are where the supports for the wing struts will be fixed. Leading edge and trailing edges are pre-shaped light weight hard wood. Wing locating dowels are same as above. All main areas have been wood glued, waterproof type. ready to be sheeted apart from the main structural areas which will have to be 'inspected' at a later date.

You can just see in the background the big tail-plane from my Tiger Moth...... which no longer looks big I'll be honest.........

The 1/8" light ply isn't the actual proper stuff from Slec, its a high quality ply from Smith Bro's. and at around £12.00 for a 8'x4' sheet this is a 1/4 of the price of the "proper stuff", cuts lovely and is only very slightly heavier weight wise The light weight hardwood came from Rushmeres

Top side of the wing is now sheeted with 3/16" medium balsa. From the leading edge to the back of the front spar is 6", I used 36"x 2" wide balsa, as it is easier to work round the curve, staggering the joints as i went. I then whizzed some balsa sheet through the old 'Band Saw' set to 10mm for the capping strips The aileron hinging area was treated to a 1/2" wide piece of hard balsa, which was then shaped, this will allow the 10 hinges to get a good hold.

This is from the wing tip end, showing front sheeting. The wing tips will be built separately then glued on after. The wing tips alone will add a further 13" to the length of each wing panel Each panel will be 102" long with a cord of 32" (a normal standard internal door is 28.5" wide!!!)

This should give you a good idea of the size, my trusty Cougar 2000 wing, which is 48" As i said earlier, the wing tip will add another 13" to the length...........

Started wing half number 2........... it always amazes me how much quicker the second one goes together I thought i had better just bolt the 2 halves together to make sure they line up................and to see roughly how big it will be.... Remember, 2 wingtips still to be added, plus the width of the fuselage...... approx. 3' 6" still to be added.

15' so far............

Update............. I've been working on the second wing, so now both wings are at the same stage, ie. top half are sheeted and capping strips have been applied. Ailerons,Wing tips and servo mounts can be built and installed at a later date, before its due to be inspected.

Fuselage

I've decided to turn it into an L4 'Grass Hopper' Army style rather than usual Yellow J3 Cub. This is going to cause some problems though. The L4 piper Cub is much more open and has a lot of windows. This has caused me a few headaches................

1- being the fact my plan is for a J3, and not an L4.

2-how do I make the window area strong enough to support the wings?

Picture below showing "57- G " 456th Parachute Field Artillery Battalion, US 82nd Airborne Division, based at Duxford, Cambs

I looked at a lot of pictures and managed to find some small plans on the net showing the difference between them. I decided to make a full ply doubler of the cabin area to help with the strength issue.

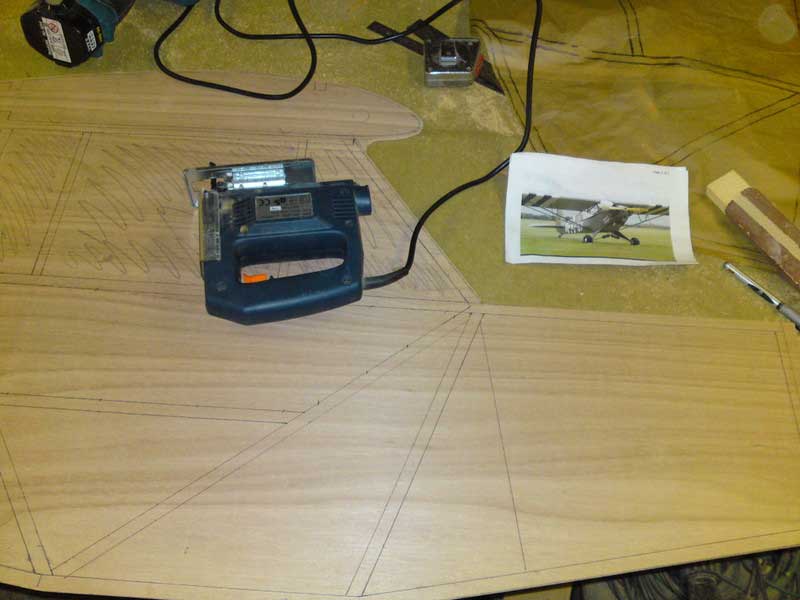

Tracing out the fuselage side and making the necessary mods, by the way, the steel ruler in the pic is 1 meter (39 1/2") not 12".................

2 doublers were then cut out of 1/8" ply, same as wing ribs

Windows were then cut out with a Jigsaw

Right hand side will have an opening door and window as per full size

Left hand side will have no door, as per full size

Next job is to built the lower structure of fuselage. 12mm x 12mm square hard wood was used. 1 side now built, just got to build the other..

Held together with clamps to check alignment, Spot on..

Still lots to do, but at least I've only got 1 of these to build...

Fuselage taking shape

It's now 9' long and a really problem to move it around

The cabin has now been sorted..a few hidden bolts for strengtheners in the cabin area should do the trick

An extra 10" or so on the nose for the motor and cowl, plus similar on the tail for rudder

Precariously balanced on a plastic bucket and workmate to show the overall size...

With a large model like this, it has to be inspected at various stages during the construction

Next Page>>

|